Loop-shaping with a MIMO PID and a setpoint filter

hinfstruct is used to design a MIMO PID controller and a setpoint filter from a standard loop-shaping arrangement as defined by Glover & MacFarlane.

Example borrowed from Genc, A. U., A state-space algorithm for designing H-infinity loop-shaping PID controllers. Tech. report, Cambridge, UK: Cambridge University, 2000.

http://www-control.eng.cam.ac.uk/aug20/aug20.html

See also P. Apkarian, V. Bompart and D. Noll Nonsmooth Structured Control Design with Application to PID Loop-Shaping of a Process. International Journal of Robust and Nonlinear Control, vol. 17, no. 14, pp. 1320-1342, 2007.

Contents

- Plant description and design objectives

- Define MIMO PID and pre- and post-compensators

- Build loop-shaping synthesis interconnection

- Tune MIMO PID controller using hinfstruct

- Time-domain simulations of actual chemical process with feedback alone

- Reduce undesirable couplings and smoothen responses using a prefilter

Plant description and design objectives

We consider a 2x2 chemical process consisting of a 24-tray tower for separating methanol and water. The transfer matrix model for controlling the temperature on the 4th and 17th trays is given as:

% actual plant with delays tf11 = -2.2*tf(1,[7 1]); tf11.inputd = 1; tf12 = 1.3*tf(1,[7 1]); tf12.inputd = 0.3; tf21 = -2.8*tf(1,[9.5 1]); tf21.inputd = 1.8; tf22 = 4.3*tf(1,[9.2 1]); tf22.inputd = 0.35; Gactual = [tf11 tf12;tf21 tf22]; % plant with exact delays set(Gactual,'outputname',{'t17' 't4'}); set(Gactual,'inputname',{'u1' 'u2'});

For synthesis purpose delays are replaced with 2nd-order Padé approximations. This leads to a model of order 12.

[n,d]= pade(1,2); del11=tf(n,d); [n,d]= pade(0.3,2); del12=tf(n,d); [n,d]= pade(1.8,2); del21=tf(n,d); [n,d]= pade(0.35,2); del22=tf(n,d); % plant rational approximation G = [-2.2*del11*tf(1,[7 1]) 1.3*del12*tf(1,[7 1]); ... -2.8*del21*tf(1,[9.5 1]) 4.3*del22*tf(1,[9.2 1])]; set(G,'outputname',{'t17' 't4'}); set(G,'inputname',{'u1' 'u2'});

Design objectives include

- Settling times of about 10 seconds for setpoint responses t17 and t4

- Good decoupling between temperatures t17 and t4.

- Noise attenuation in the high frequency range.

- Good robustness margins as defined by MacFarlane and Glover (1990). Margins are relative to coprime factor uncertainties. In general, 25% uncertainty (H-infinity norm less than 4) is considered a good design.

Figures 1 and 2 are equivalent through the transformation

The loop-shaping interconnection of figure 2 is used to synthesize a MIMO PID controller. The overall controller is then finally obtained as

This is an composite of a MIMO PID and a roll-off filter W2 which has better noise attenuation than pure PID controllers.

Define MIMO PID and pre- and post-compensators

Pre- and post-compensators reflect desired loop shapes:

W1 = [tf([5 2],[1 0.001]) 0; ... 0 tf([5 2],[1 0.001])]; W1i = 1/W1; W2 = [tf(10,[1 10]) 0; 0 tf(10,[1 10])]; sigma(W1,W2,'r--'); grid; legend('W1 performance','W2 roll-off'); title('pre- and post-compensators');

Build loop-shaping synthesis interconnection

Describe MIMO PID controller

Kp = realp('Kp',zeros(2)); Ki = realp('Ki',zeros(2)); Kd = realp('Kd',zeros(2)); tau = realp('tau', 1); % non-zero is realizable Kpid = Kp + Ki*tf(1,[1 0]) + Kd*tf([1 0],[tau 1]) ;

Describe synthesis interconnection loop

W1.u = 'w1'; W1.y = 'y1'; G.y = 'y'; W2.u = 'y' ; W2.y = 'y2'; Kpid.y = 'u'; Sum1 = sumblk('z1 = w2 + y2',2); Sum2 = sumblk('s2 = y1 + u',2); Kpid.u = 'z1'; G.u = 's2'; W1i.u = 'u' ; W1i.y = 'z2'; % connect blocks together T0 = connect(G,Kpid,W1,W1i,W2,Sum1,Sum2,{'w1','w2'},{'z1','z2'});

Tune MIMO PID controller using hinfstruct

op = hinfstructOptions('RandomStart',3); % multiple restarts may improve [T,gam] = hinfstruct(T0,op);

Final: Peak gain = 2.92, Iterations = 81 Final: Peak gain = 2.91, Iterations = 144 Final: Peak gain = 2.92, Iterations = 155 Final: Peak gain = 3.69, Iterations = 66

A value of

1/gam,

ans =

0.3431

relative coprime factor uncertainty has been achieved

Display controller parameters

T.Blocks.Kp.Value, T.Blocks.Ki.Value, T.Blocks.Kd.Value, T.Blocks.tau.Value, % Retrieve MIMO PID controller KpidFinal = getNominal(Kpid,T); % Deduce final controller Kfinal = KpidFinal*W2 ;

ans =

2.5960 -0.7038

-1.1410 -2.4019

ans =

0.8455 -0.2434

0.0461 -0.8983

ans =

0.7437 -0.2777

-1.5550 0.0193

ans =

0.1523

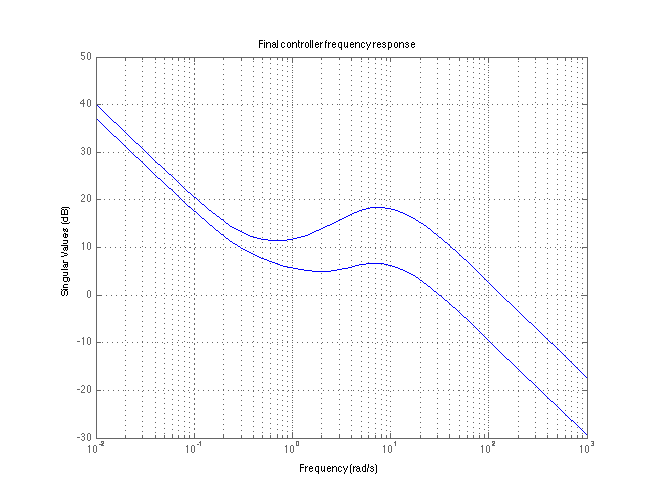

Display controller frequency response and check roll-off properties. Remind that controller is a composite of a MIMO PID and a roll-off filter W2.

figure(2); clf; sigma(Kfinal); grid on; title('Final controller frequency response') ;

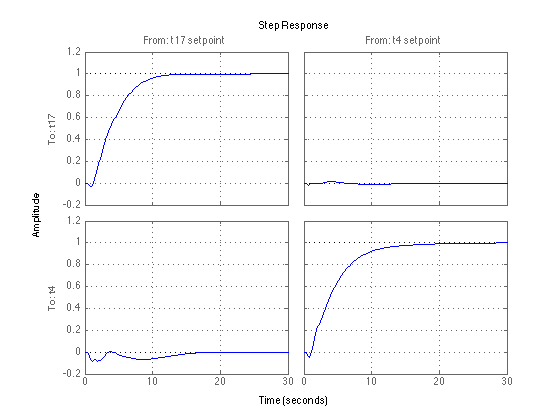

Time-domain simulations of actual chemical process with feedback alone

CLsim = feedback(Gactual*(-Kfinal),eye(2)); set(CLsim,'inputname',{'t17 setpoint' 't4 setpoint'}); figure(1); clf; step(CLsim,30); grid;

Unpleasant distorted responses are obtained along with strong couplings between t17 and t4. Using PID feedback alone is not sufficient in this application. A setpoint filter is therefore introduced to achieve better performance. Altogether, we end up with a 2-DOF control structure.

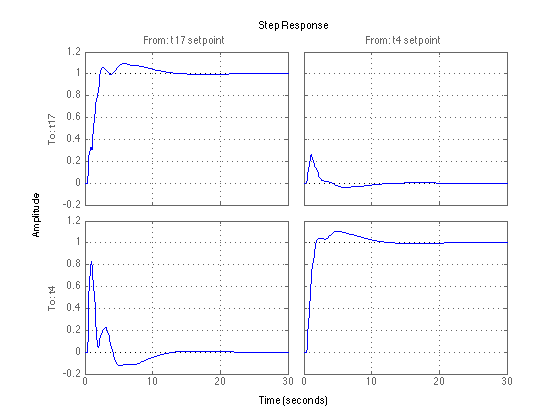

Reduce undesirable couplings and smoothen responses using a prefilter

A prefilter shapes setpoint inputs to enhance responses and reduce couplings between t17 and t4. Prefilter tuning can be based on a model reference tracking strategy. Note the feedback block is fixed which leaves unchanged robustness margins.

s = tf('s'); Gref = blkdiag(1/(3*s+1),1/(3*s+1) ); % reference model

Define setpoint filter with classical structure

tau1 = realp('tau1',1); a1 = realp('a1',1); b1 = realp('b1',1); % realizability tau2 = realp('tau2',1); a2 = realp('a2',1); b2 = realp('b2',1); % realizability F = [tf(1,[tau1 1]) tf([a1 0],[b1 1]);tf([a2 0],[b2 1]) tf(1,[tau2 1])] ;

Form synthesis problem as minimization of tracking error.

T0 = (feedback(G*(-Kfinal),eye(2))*F - Gref) ; % tracking error % Tune setpoint filter op = hinfstructOptions('RandomStart',3); % multiple restarts may improve [T,gam] = hinfstruct(T0,op); Ffinal = getNominal(F,T);

Final: Peak gain = 0.441, Iterations = 35 Final: Peak gain = 0.446, Iterations = 44 Final: Peak gain = 0.441, Iterations = 36 Final: Peak gain = 0.444, Iterations = 39

Time-domain simulations of actual chemical process with feedback and setpoint filter in place.

CLsim = feedback(Gactual*(-Kfinal),eye(2))*Ffinal; set(CLsim,'inputname',{'t17 setpoint' 't4 setpoint'}); figure(3); clf; step(CLsim,30); grid;